Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

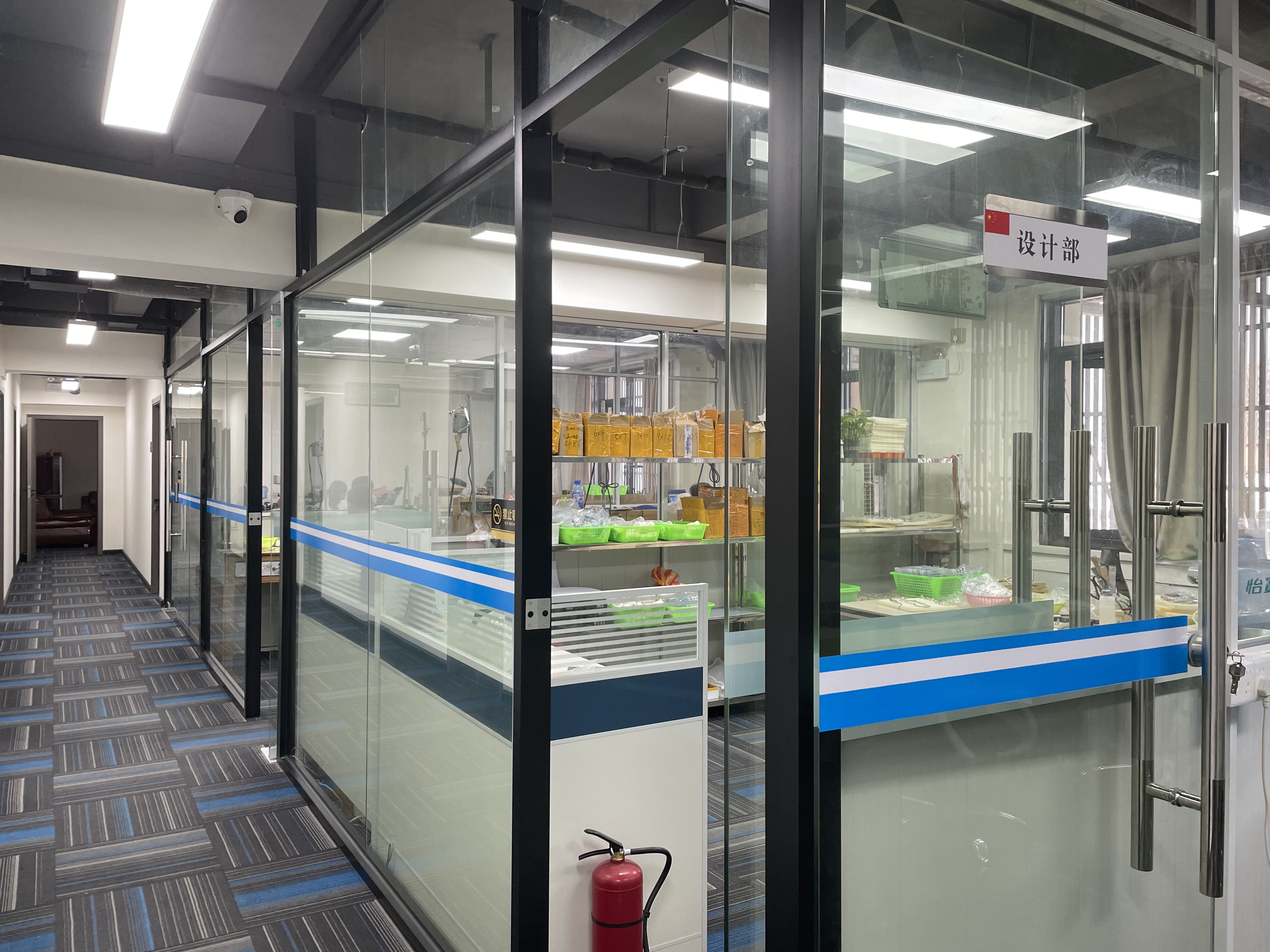

Jewelry making is a complex art that blends creativity and precision to bring precious metals and gems to life. At Rachel jewelery.co. We have mastered this art, delivering beautifully crafted pieces.

1.That reflect our commitment to quality and craftsmanship.

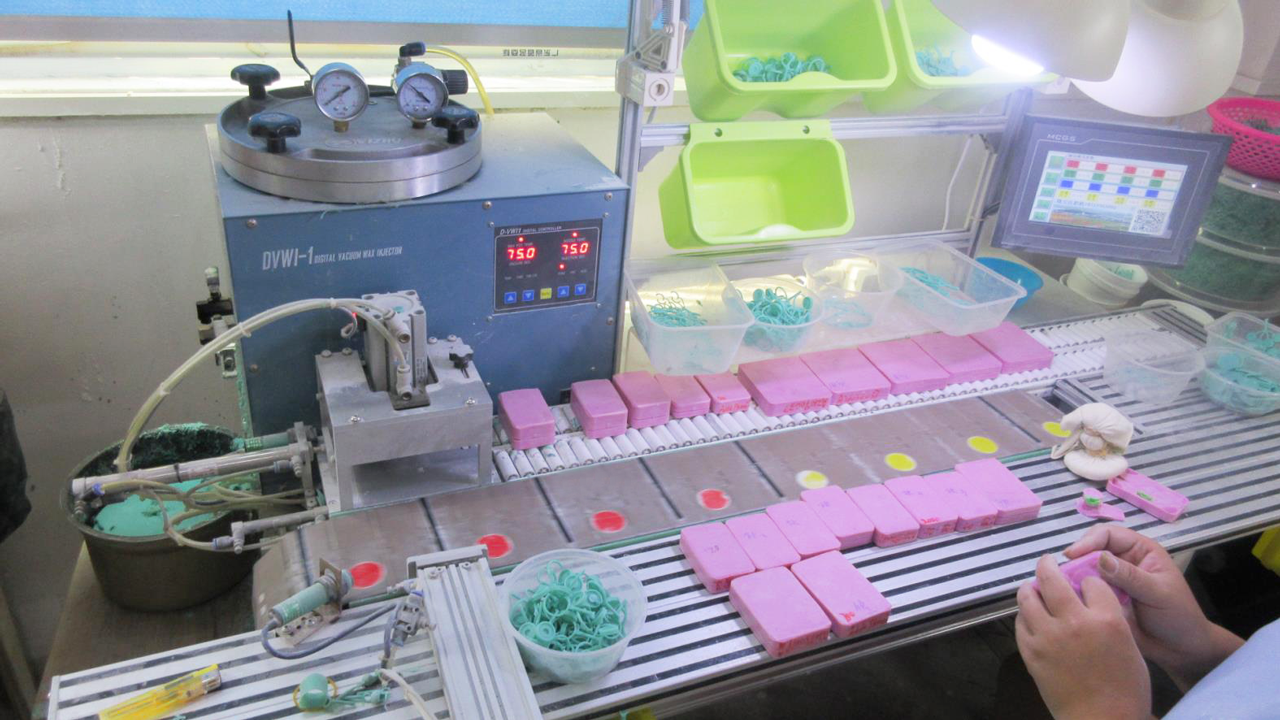

Through this article, we will explore the various stages of jewelry manufacturing, highlighting the meticulous craftsmanship and skilled artisans behind each unique piece. Preliminary design and wax mold making The journey of a piece of jewelry begins with a concept that brings the vision to life through detailed sketches and computer-aided design. Once the design is complete, the next step is to make a wax model. This model acts as a prototype, allowing for precise adjustments before entering the casting stage.

2.Casting process After refining the wax model, the casting process begins.

This stage involves creating a mold from a wax model and then filling it with molten metal. The choice of metal, be it 925 silver, 18K gold, or brass, is crucial as it determines the quality and appeal of the piece. Rachel Jewelry.co. The company prides itself on using only the highest quality materials to ensure the durability and beauty of each piece.

3.Assembly and welding

Once the metal has cooled and solidified, the parts are carefully removed from the mold and assembled. This stage usually involves welding, joining various parts together to form a complete part. Our skilled craftsmen handle this process with care, ensuring that each joint is seamless and secure.

4.The art of stone setting

Gemstone setting is another important aspect of jewelry manufacturing. Whether it's a sparkling diamond or a vibrant gemstone, setting these stones requires precision and dexterity. Our craftsmen specialize in a variety of Mosaic techniques, ensuring that each stone is positioned safely and aesthetically to enhance the overall design.

5.Polishing and quality control

The final stage of jewelry manufacturing includes polishing and quality control. Polishing can enhance the gloss of the workpiece and make it look more perfect. Quality control is crucial; Every product is rigorously tested to ensure it meets our high standards. At Rachel jewelery.co. We believe that perfection is in the details, and each piece reflects our commitment to excellence.

Jewelry manufacturing is a complex process that combines artistic and technical skills. From the initial design to the final polishing, each stage is the key to creating a piece that is not only beautiful but also of the highest quality. Rachel Jewelry.co. With its decade-long experience and dedication to craftsmanship, we continue to produce fascinating and inspiring jewelry. For more information about our products and services, please visit our website.